A Limpet L5 system has been installed at the Bechtel dairy facility in Schwarzenfeld, Germany. The dairy stores its product in an enormous, low-oxygen high-racking facility. The reduced level of oxygen is designed to lower the risk of fire, but it also increases the exertion required by workers to climb the 30-metre ladders that run up the side of the storage racks. In the event of an emergency, it would also make rescuing an unconscious casualty difficult. Limpet Technology's expert partner Bornack GMBH, saw an opportunity to improve the situation through the provision of Limpet powered climb assist and rescue systems and the unit was successfully installed into the facility in January 2018.

LIMPET 90% CLIMB ASSIST & rescue system brings relief for workers in low-oxygen storage facility2/21/2018

183 Comments

Limpet Technology is now offering hitch mounting plates that allow Limpet multifunctional access systems to be quickly and simply anchored to the back of service vehicles. If you need to rapidly deploy fall prevention, powered climb assist, load lifting, personnel lifting or rescue capability for access to tall structures or confined spaces, then the hitch mount solution is for you.

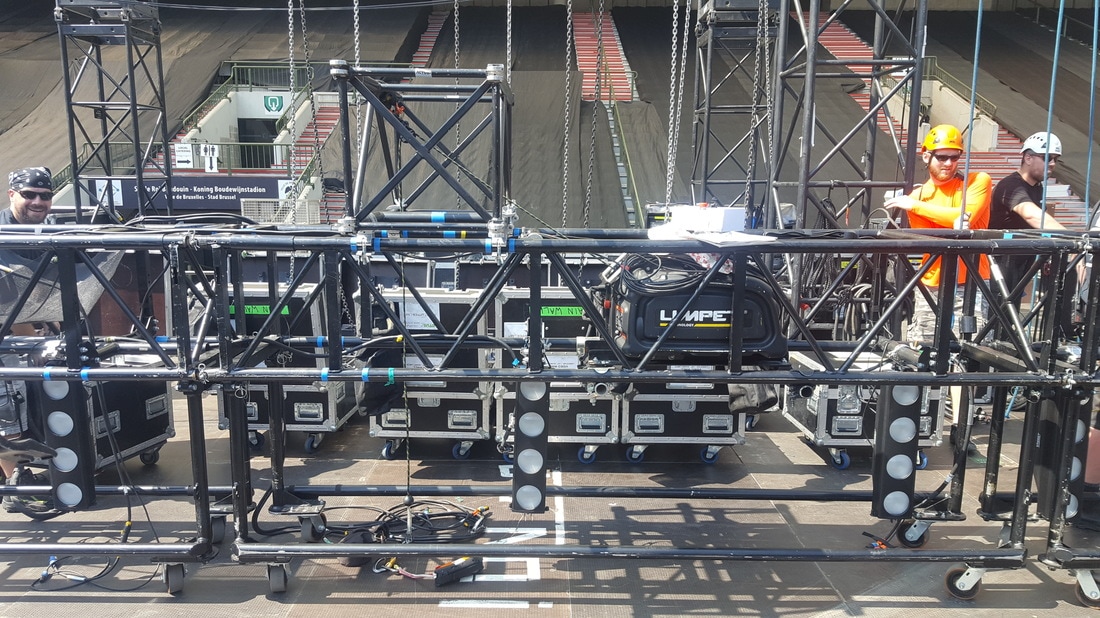

As can be seen in the pictures below, the mounting plate can be oriented vertically, horizontally or at 45 degrees, for whatever line path is most appropriate to the application. In this way, the line can be taken direct to the top of a structure or to a pulley lower down and then diverted upwards. If you have teams that are inspecting or maintaining telecoms or electricity transmission towers, met masts, buildings, silos or bridges, then having a hitch mounted, remote control operated Limpet® will make their work faster, easier and safer. For more information contact [email protected] Limpet Technology partnered last year with Bornack Gmbh to offer Limpet multifunctional height safety and industrial access systems to German speaking markets. Bornack has just released a Limpet promotional video, which we think looks great and shows off Limpet systems being used for different applications and industries; nicely capturing its versatility and ease of use. We'll be attending the A+A and Husum Wind Energy trade shows with them in the coming months, so if you would like to meet up please get in touch. So who was your favourite Glastonbury performer? Was it Radiohead? Katy Perry? Ed Sheeran and his loop pedal? For us it has to be the Limpet E5...on duty throughout the festival to lift and lower spot light operators into position. Quick, safe and reliable. Limpet is the complete opposite of your typical rock and roll star! Michael Eavis has confirmed that Limpet will be invited back next year to headline on the Pyramid Stage! The incredible logistics of a global stage tour never ceases to amaze. When Russell, head rigger for Coldplay’s ‘A Head Full of Dreams’ tour, called asking if we’d mind meeting them to give their Limpet® E5 units a quick check-up, the problem was where to rendezvous. Should it be Hannover on Monday, Warsaw on Wednesday or Brussels on Friday? In the end Brussels was locked in and Eddie headed off to intercept Chris Martin and co. Happily all Limpets were doing fine; perhaps a little damp from having been out in a monsoon or 3 during the Asia leg of the tour, but all A-OK and ready for the US of A in August.

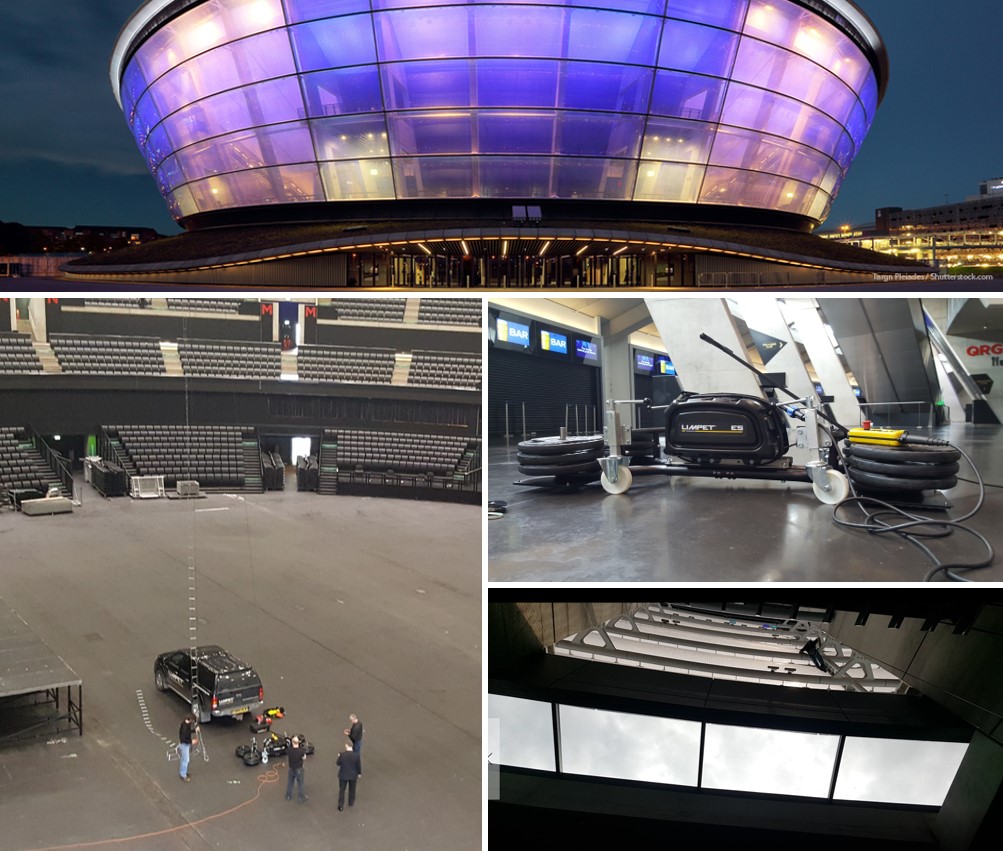

It's been a busy week at Limpet with a focus on staged entertainment. Not only did we deliver units to our fantastic new customer NEC Group and do a great demo to the National Arena Association folks at the SSE Hydro (see blog entries below), but we also paid a visit to NEG Earth, our best UK staging customer, to visit their fantastic (& rebuilt) facility in West London. The band MUSE came up a few times in these conversations as they were the first proper tour that Limpet E5 units were put out on (2nd Law). And from what we hear they'll be out with them again on the Drones tour. Just as a reminder, the two videos below give a very quick and easy snapshot of how Limpets are taking industry safety forward. Both show follow-spot light access at Muse live events. BUT with very different approaches. No extra commentary needed

Last Friday saw us out at the SSE Hydro demonstrating a Limpet E5 and jackup anchor frame to a group of health and safety managers from Venues under the National Arenas Association (NAA) umbrella. The demo saw us drop a 22 metre wire rope ladder from the mother grid to demonstrate the climb assist functionality of the system. With 90% climb assist, the easiest way to climb the ladder is actually to not use your feet at all and just pull using only your arms. That way you don't need to bother with the rather fiddly technique that's needed to perfect the art of unassisted rope ladder climbing. Of course the easiest way of all is to just use the up button on the remote control hoist and to leave the ladder completely untouched! Some people consider that to be cheating, but it's the application that's seen us win most business in the touring stage production sector, with Limpet's being used as the means of lifting the follow-spot operators into their chairs.

After the NAA demo, we took a tour of the Hydro and were able to try out the use of the Limpet as a means of easily accessing and fall protecting work to clean and maintain the inside of the translucent, air filled, ETFE walls that are the most distinctive feature of the venue. After rolling the Limpet out of the arena on its jacked up anchor frame, we parked it below the leaning outer wall and rigged the line up and got to work. 30 minutes later everyone was covered in dust, but we'd been successful in proving its usefulness for that application. Should Wind Turbines Have Back-up Powered Access Systems for when service lifts are unavailable?4/20/2017 We recently got a look at a Report that summarised the debates and conclusions from a workshop held by the G+ late in 2016. The Workshop and Report, titled “G+ Safe by Design: WTG Service Lifts”. This workshop, which is part of a series, aimed to explore industry operations and technologies with a focus on Safe by Design principles. This workshop topic was driven by an incident in September 2015, when a service lift failure resulted in a technician fatality and the day was divided into themes which looked at service lift design and specifications, service and maintenance and the human impact of ladder climbing in the event of service lift unavailability.

One key conclusion of the report was that wind energy companies should “consider the merit/ feasibility of installing a back-up solution should the primary service lift be unavailable”. Another was that “In future, perhaps driven by taller turbine towers, operators could see two systems installed to have redundancy in powered access systems”. A third conclusion was to “consider a review of the various industry standards for fall arrest systems, reflecting on any recent developments or potential to improve these through integrating best practice on training.” As the supplier of the world’s best climb assist systems, which also happen to be the world’s best fall arrest devices, we found these points particularly interesting. In the context of multi-million Pound turbines, we think that the provision of a high quality powered ladder access system will not only make technicians safer and less stressed, but will also lead to productivity benefits and cost savings for operators. We were interested to read in a Report titled "Optimised Tower Design for Increased Hub Heights" that "Data from the Fraunhofer IWES Wind Monitor showed that in 2013, 33% of all new turbines installed in Europe had hub heights in the range of 120-140 metres" and that "In mountainous regions, where winds are naturally stronger at height, 80% of turbines constructed in 2013 were in excess of 120 metres." The April 2017 ORE Catapult report “Helicopter Crew Transfer at Westermost Rough” mentions that the use of a helicopter for technician transfer helicopter was partly justified by the fact that the service lifts were inoperable during the period of maintenance work and that the technicians would otherwise have had to climb the access ladders. If the cost of helicopter charters can be justified over a short period as a result of service lift unavailability, we believe that installing dedicated access systems will be a much more cost effective solution. We hope to engage proactively with the wind energy industry on this topic and will be writing more on the subject soon. limpet rolls out new jackup deadweight anchor rescue & Access system with nec at barclaycard arena4/10/2017 Our trainers were at the Barclaycard Arena last week, delivering two Limpet E5 units complete with brand new jack-up deadweight anchor frames. These were developed specifically for the NEC rigging teams, who wanted a system that could be rolled out (literally) in the event of an emergency and quickly positioned on the arena floor. As the video shows, the riggers took it all in their stride and were soon running rescue scenarios from the catwalk and follow-spot light gantry twenty metres up. The Limpet team was back out on the telecoms trail a couple of weeks ago, with the system being trialled by respected telecoms contractors HF Comms at an Arqiva site not far from Edinburgh (which made for a nice change!) Happily, the HF team were very happy with their Limpet, which with its 110v supply, up to 270m of dyneema line, wireless remote and pendant controllers and a lifting capacity of 250kg was the perfect lifting tool for their project to replace various antenna on the 45 metre high tower. The team saw clear benefits compared to the capstan style winches they are accustomed to working with. The main ones being:

If you'd like to hear more or have a demo be sure to get in touch! |