Limpet® Multifunctional height Safety Systems

Limpet® systems combine robust hardware with sophisticated electronics and software to make smart, rugged height safety and industrial access solutions that deliver exceptional performance across their multiple functions.

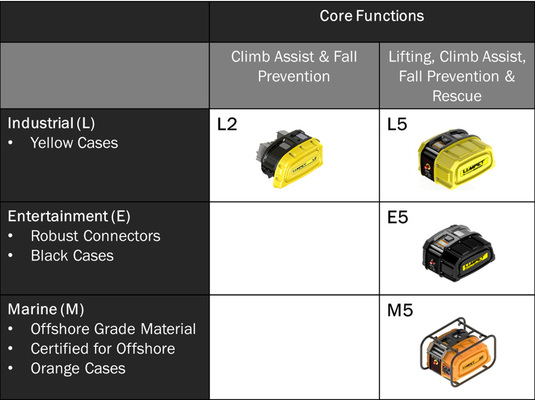

We currently offer 4 different types of Limpet® safety system

We currently offer 4 different types of Limpet® safety system

|

Limpet® L2

Best for...safe and effortless long ladder climbs Limpet® L5 Best for...onshore personnel and load lifting, rescue and evacuation Limpet® E5 Best for...personnel and load lifting, rescue and evacuation where system is used portably Limpet® M5 Best for...offshore personnel and load lifting, rescue and evacuation |

|

Hand Built in ScotlandLimpet® products are designed with very high safety factors on load bearing parts (minimum 15x). As a result, low stress is placed on key components, which results in high reliability in the field, extended working life and delivering a lower total cost of ownership for customers

In addition to our design work, all Limpet® systems are manufactured and tested by experienced technicians in our workshop in Edinburgh Scotland |

Limpet® Accessories

We have developed a range of optional accessories that further improve the portability of Limpet® for work teams tackling the very toughest height safety and access challenges.

The Limpet® X-Frame is an EN certified dead-weight anchor. It is quickly assembled and provides the ideal means of anchoring the Limpet® if it is being used as a portable solution and/ or where no fixed anchor is available.

The Limpet® Manual Handling Frame is fixed to the Limpet® unit and provides both a means of carrying the system to its position of use and an element of protection from major knocks. An enclosure for the Display Control Unit is also available.

The Limpet® Fairlead Roller is fitted to the front of the Limpet® unit and provides further protection for the safety line as it exits the machine.

Limpet® Servicing & Maintenance

|

Limpet® units have been engineered to provide very high safety factors and reliability in the field. Scheduled servicing and maintenance is light with no requirement to remove the side casings on the units for the first twelve years of service. Systems can be serviced on-site with no need to return to a service centre, keeping costs low.

Limpet Technology and its representatives can perform annual servicing under an Extended Warranty agreement or we can train customers in Limpet® maintenance so that they can do it themselves. In short, our philosophy is to give our customers maximum flexibility in the upkeep of their Limpet® fleet and will deliver whatever level of service or tools is required. Please contact us to find out more |